The versatile world of wood

Plants use the sun's energy to produce sugar, which trees can convert into wood. Wood is an environmentally friendly building material that has been used by people for a long time. Today, the entire wood value chain provides around 80,000 jobs in Switzerland, which corresponds to approximately 2% of all employees in Switzerland. For over 150 years, Switzerland has proven that sustainable forestry is possible. To continue the success of the Swiss wood industry, customers who value Swiss wood are needed.

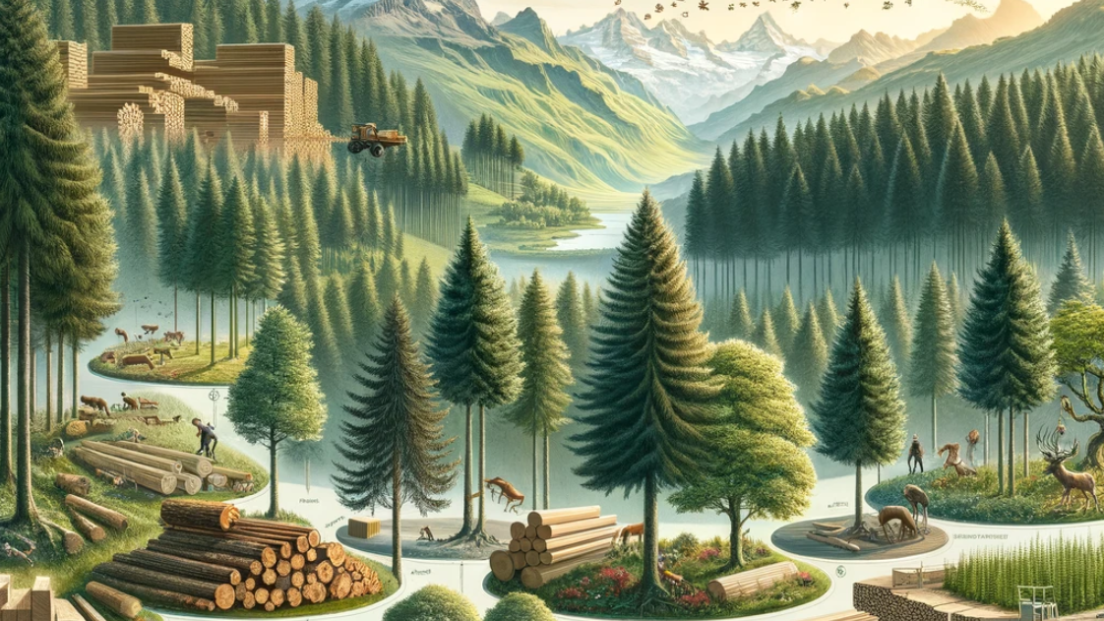

Utilisation of the wood

After a certain time, the tree reaches its growth limit. This is the perfect time to fell the tree – it is ready for harvesting. Depending on the tree species, the time until it is ready for harvesting varies between 60 and 150 years. Until then, the tree has had enough time to reproduce through seeds in the gaps in the forest. The plants in the young forest that are best adapted to the local climatic conditions prevail. In this way, the forest remains healthy thanks to natural selection. During thinning, desirable and well-grown trees are left standing as future trees. The abundance of light in the gaps created by felled trees allows a variety of shrubs and annual plants to colonise the ground – increasing biodiversity in a forest managed in this way.

The majestic forest of Switzerland

Around a third of Switzerland’s total land area is covered by protected forest. This forest provides protection against natural disasters, is a habitat for animals and plants, a place for recreation and leisure and a source of wood. Sustainability is a fundamental principle that requires the forest to fulfil all these functions in the long term without harvesting more wood than grows back. Enough wood grows in the Swiss forest every ten minutes to build a detached house. Around 60% of Swiss forests consist of conifers and 40% of deciduous trees. A large proportion of the wood felled is processed into sawn timber and planed products, while 10% is used for the production of paper and wood-based panels. A quarter is used directly as firewood. Around 10 million cubic metres of wood grow in Switzerland every year, only half of which is used. Wood is a durable material that regrows itself and plays an important role in the ecological balance. It is therefore sensible and advisable to use our own wood.

Characteristics of wood

Wood is a light yet strong material that can bear fourteen times more weight in relation to its weight than steel. Due to its natural cell structure, the static properties of wood are directional. Wood is most resistant along the grain, as it can withstand a hundred times higher tensile forces and four times higher compressive forces in this direction than across the grain. Understanding these static properties is of crucial importance when building with wood. In addition, the warm and pleasant feel of wood gives rooms a special atmosphere. The wood fibres in the installed wood constantly react to the air humidity and thus contribute to a balanced room climate.

Variety of wood species – differences in the forest and in the home

Not all woods are identical. The characteristics and appearance of wood vary depending on the tree species – there is a wide range from light to heavy, soft to hard and light to dark. Each type of wood therefore has specific properties that are suitable for different purposes. For example, the heartwood of sweet chestnut or oak, which is preserved with natural tanning agents, is particularly suitable for outdoor use, while long-fibre ash is used for parts subject to heavy wear. Fine-fibre woods such as beech or maple are used in furniture production. Promoting different tree species by using different types of wood helps to increase biodiversity. Each tree grows individually, so its wood may have more or fewer knots, wider or narrower annual rings, be slightly lighter or darker in colour and grow crooked or straight. Each tree trunk and section is utilised according to its qualities. Selected logs of high quality are processed in sawmills into a variety of sawn products such as beams, boards, laths, posts and glulam. Timber that is crooked and knotty or small diameter logs are converted into chipboard and fibreboard in panel mills. The best qualities are processed into veneer. From both an ecological and an economic point of view, it is crucial to determine the appropriate quality for the respective area of application in advance with the supplier.

Wood-based materials

The large formats of wood-based materials have made an important contribution to the development of modern timber construction. The production of wood-based materials follows a simple principle: the wood is chopped into boards, chips or fibres and then shaped into a new form with the help of glue. This results in products with standardised properties in a fixed thickness and size. Wood-based materials therefore offer added value and open up a wide range of design possibilities with wood. As a cost-effective building material for everyday use, wood-based materials are indispensable and are available in a wide range from timber merchants and DIY stores.