BFH researchers develop sustainable binder for wood-based materials

In an Innosuisse project, researchers from the Institute of Materials and Wood Technology IWH at the Bern University of Applied Sciences BFH are developing a new mineral binder for the production of wood-based materials. This should make them more sustainable.

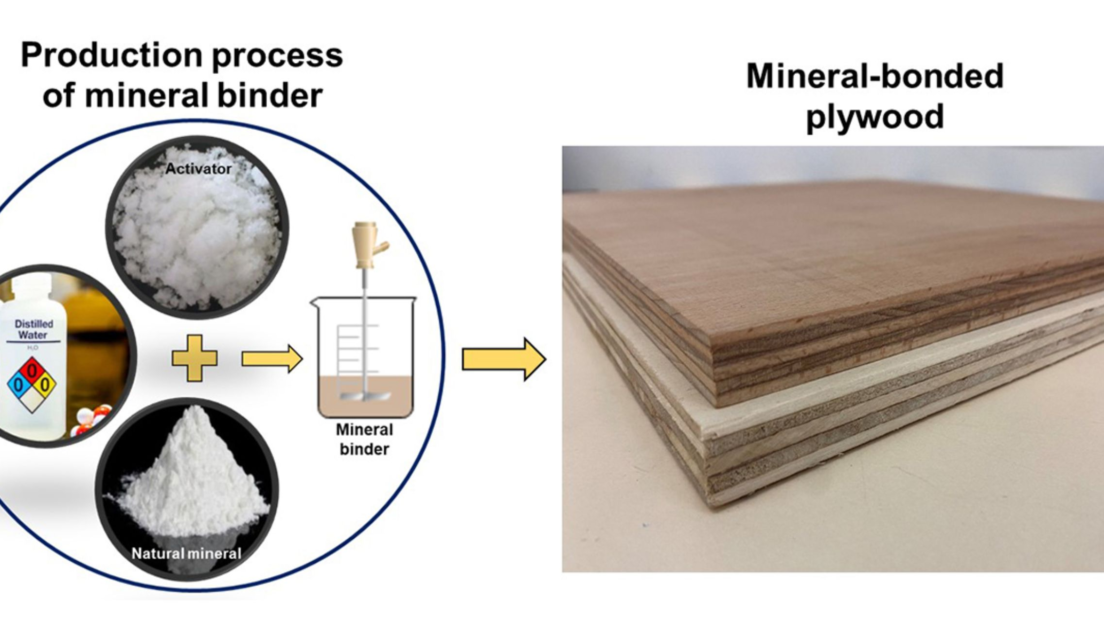

The sustainability of wood-based materials such as plywood or wood fibreboard is largely determined by the binder used. Formaldehyde-based binders, as they are mainly used today, are responsible for the majority of CO2 emissions from wood-based materials. Moreover, their formaldehyde emissions are often considered problematic. Research into the development of mineral binders has therefore been going on for several years, including at BFH. Compared to a formaldehyde adhesive, these binders have almost 80 percent lower CO2 emissions. A new mineral binder for the production of wood-based materials is being developed by researchers at the BFH’s Institute of Materials and Wood Technology IWH in a recently launched Innosuisse project. In the project, the researchers are working together with the Swiss company Omya International AG, a leading global supplier of calcium carbonate minerals.

Less than 20 per cent binder

The development by BFH and Omya International AG is initially intended for the production of mineral-bonded plywood. The finished boards are to contain less than 20 per cent binder and have the mechanical properties of conventionally produced plywood for interior use. The binder should be able to be cured with heat, which will enable a fast manufacturing process and thus make the product competitive.